Share

The Environmental Protection Agency of the Executive Yuan (hereinafter referred to as the Environmental Protection Agency) held the "108 Incineration Plant Incineration Ash Reuse Technology Forum and the 107 Year Waste Incineration Plant Incineration Bottom Residue Reuse Review and Assessment" in Tainan City on October 24. Award Ceremony", in which Li Advantage Environmental Protection Co., Ltd. (hereinafter referred to as Li Advantage Company) was awarded the "Bottom Slag Treatment Contribution Award" by the Environmental Protection Agency's incineration bottom slag recycling inspection team. Power Advantage is the company with the largest incineration bottom slag treatment capacity in Taiwan, and is the only company in the bottom slag treatment industry that has won this honor. In addition to working on the bottom slag treatment of incineration plants, he is also specialized in metal sorting, with the goal of reducing the impact of environmental pollution, in order to build urban mining and deepen Taiwan's vision for a new international blue ocean.

Representing the Power Advantage Company to receive the award were General Manager Liao Zongming and Deputy General Manager Xu Tianshun. At the same time, Vice General Manager Xu, who is also a technician of environmental engineering, has very high expectations for the company. He said that in the early stage, the general waste incineration treatment system in Taiwan was of the mixed combustion type, and most of the waste entering the plant was not classified and screened. Insufficient volume of landfills has caused worries about the future operation of the landfills. At present, due to the maturity of incineration bottom slag recycling technology, there are many application examples in advanced foreign countries. Based on the goal of sustainable resource reuse, to promote the reuse of incineration bottom slag resources, and to implement the concept of circular economy, it is extremely urgent to promote the current stage. primary environmental issues.

The approved bottom slag processing capacity of Lixiang Company is 41,200 metric tons per month, and the object to be treated is the incineration bottom slag of the public waste incineration plant (processing code D-1103). And Shanlinshui Environmental Engineering Co., Ltd. (hereinafter referred to as Shanlinshui Company), which belongs to the environmental engineering business group of Lili Group, became the largest shareholder of Lili Advantage Company in November 106, and Lili Advantage became the Shanlinshui Company. After becoming a subsidiary, it has adhered to the concepts of "innovation", "professionalism", "quality" and "service", and continued to develop in the fields of "environmental resources" and "recycling".

Taking European countries as an example, the average utilization rate of bottom slag is 60%, and it is as high as 90% in Denmark and the Netherlands. Currently, in order to promote the reuse of incineration bottom slag, the Environmental Protection Agency continues to announce amendments to the "Management Method of Incineration Bottom Slag Reuse in Waste Incineration Plants." ". The incineration bottom slag after the screening, crushing and other processing procedures can be used as the bottom layer and base layer of road graded aggregate, base and embankment filling, controlled low-strength backfill material, low-density permeable concrete, asphalt concrete, Bricks, cement raw meal and sanitary landfill cover soil (not used as final cover soil) etc. In short, if the bottom slag is properly treated and reused, it can replace the mining of some sand and gravel raw materials, protect Taiwan's land resources, and effectively recycle and reuse the incineration bottom slag resources, which can also achieve the environmental 3R goals of a circular economy: Reduce (reduce use), Reuse (make the best use of things), Recycle (recycling). At present, Taiwan produces about 880,000 tons of bottom slag a year, and the recycling rate is about 61. 6%, of which the annual processing capacity of Li Advantage Company is about 200,000 tons, which has made outstanding contributions to the domestic bottom slag treatment.

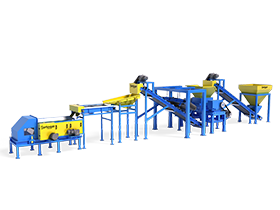

The bottom slag treatment adopted by Li Advantage Company belongs to the whole-stage wet treatment process. The process sewage is collected in the water storage tank and treated, and then recycled in the process. The operation process is that after receiving the bottom slag from the waste incineration plant, through the procedures of drum screening, crushing, wet screening, magnetic separation, eddy current sorting, etc., the bottom slag is properly treated and screened out. Separation rate > 95%, non-ferrous separation rate > 85%) and derived waste; this year, a high-performance crusher and an updated eddy current system were introduced to improve equipment performance. Power Advantage is the first manufacturer in Asia to adopt wet processing technology, and has self-developed and registered technology patents on both sides of the Taiwan Strait. Using water as the treatment medium can greatly shorten the time and storage space required for natural aging, and It can achieve high-quality recycled pellets and improve the acceptance of engineering users.

Finally, Vice President Xu pointed out that in the past, the pellets produced by the bottom slag screening would have peculiar smell, which caused troubles for the manufacturers at the end of the use. The wet sieving method can effectively reduce the odor, increase the curing rate and stabilize the quality. The selected resource-based products and specifications are more acceptable to manufacturers. The improvement of the equipment is fully prepared and confident in the draft of the "Management Method for Reuse of Incineration Bottom Slag in Waste Incineration Plants" announced by the Environmental Protection Agency on October 15, 108, and will be prudent And the attitude of striving for perfection will meet every challenge in the future, and improve the technology to move towards incineration bottom slag treatment 2.0.

Article reposted: https://udn.com/news/story/6848/4137007