Share

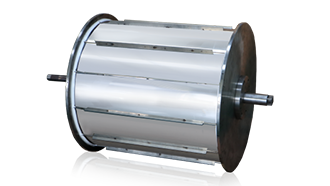

Drum Magnetic Separator is designed to separate metal particles from slurries, granules or powders. When materials were transmitted through the drum magnet, the continuous self-cleaning separator will capture the metal to improves the sorting result, increases sorting efficiency, and most importantly decreases non-essential cost. It is ideal for applications where there is a high level of ferrous and para-magnetic contamination.

As a drum magnetic separator manufacturer Nian Hung (Sortinger) is dedicated to providing recycling solutions. We encounter that clients are concern about whether the separator is suitable for their sorting process because they cannot feel it through photos and demo videos. Under these circumstances, Nian Hung provides a materials test center solution for the potential client could test their materials before they make the purchases.

Customized Material Testing Services in Various Magnetic Separator Machine

Adhering to the principle of "taking customers' needs as a priority" Nian Hung provides customers with material testing services. Our design group would further discuss customized planning according to clients' factory size or material characteristics, to ensure the best solutions for their material.

|

|

|

|

Iron and copper before sorting

|

Iron after sorting

|

Copper after sorting

|

The owner of the glass mold processing plant from Mr. Chang personally visited the test center with his material, waste CNC ferrous, and copper chips. At the first trial, we noticed the "contact-typed" magnetic separator was not suitable for the material as curled CNC chips would coat with each other. At the second attempt, we tried the "far-distance" magnetic separator, the sorted rate was greatly improved. After the experience, Mr. Chang requested Nian Hung to customize a magnetic separator. The original magnetic separator that Mr. Chang owned was not functionally satisfied, not only did the feeding port too narrow to feed material smoothly but the PU belt was often damaged due to metal friction. What annoyed him the most is the small iron filing stuck inside the bearing because of magnetic permeability. All these factors reduced sorting efficiency greatly.

Therefore, after learning Mr. Chang's consideration, we designed a "far-distance" drum magnetic separator equipped with a vibration feeder. Discharging the belt conveyor, the vibration feeder can evenly spread out the processed metal filling with the one-meter vibrating distance. Ferrous will be taken away within 15 cm of the drum magnetic while the remaining copper filling falls to another export.

With a Customized Drum Magnetic Separator, Nian Hung able to bring the benefit that includes:

• No more uneven feeding issue during sorting

• No more belt maintenance

• Drum Magnetic is protected with sealing pieces on both sides

• No operating energy is required on the drum magnetic separator

In addition, on the day of installation, Nian Hung sent an English-speaking specialist to teach the Filipino workers how to operate the machine. This customized service allows Mr. Chang to save costs in terms of labor and time and improves the sorting efficiency.

Choose Nian Hung for Magnetic Separator. Feel free to contact us today for more information.

Nian Hung focuses on the development and innovative application of Eddy Current Sorting technology since 1982. Our mission is to integrate diverse sorting technology to build quality and reliable magnetic sorting machines.